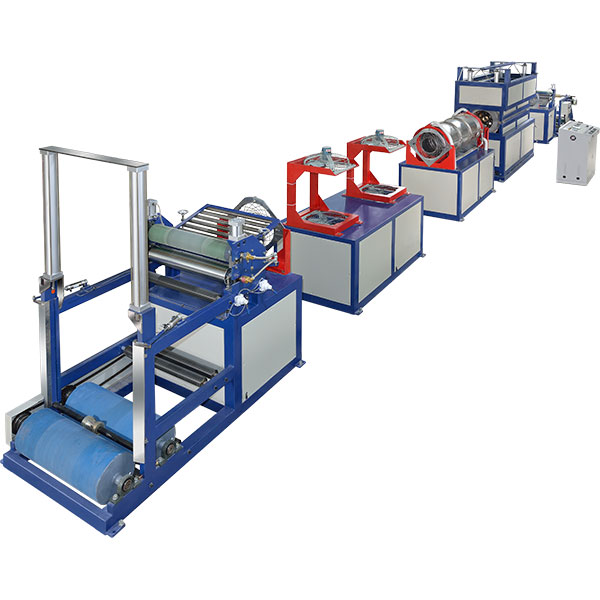

MX-650

This production line can efficiently make the inner surface of tubular woven cloth laminating with the outer surface of tubular inner lining film by bonding device.The inner lining film is double-layer & co-extrusion blowing film which is 0.03mm to 0.04mm thick.The inner layer of tubular lining film is made from Low-Density Polyethylene(LDPE),the outer layer of it(the layer which is bonded to the woven cloth) is made from Ethylene Vinyl Acetate Copolymer(EVA).The outer woven cloth is mainly made from polypropylene(PP). The melting temperature of EVA is lower than the melting temperature of LDPE and PP,and the melting EVA film can be bond to the PP woven cloth.We can take advantage of this features to bond and laminate the inner lining tubular film and outer tubular woven cloth together at appropriate temperature by series of procedures.

The inner lining film can be laminated with the woven bag in a lower temperature,so the bags produced by this line have fantastic physical characteristics.It is flexible,strong,durable,and has good comprehensive performance.In the bonding process,the bags are flattened by heating,so the bags are smooth and beautiful.The advantages of common woven bag with separated inner lining film and the advantages of laminating bag all appear in bags produced by this machine.These bags are new age packing product and they are used widely in multiple area.

The cost and price of the bag produced by this machine is slightly higher than the same type and same quantity common woven bag with separate inner lining film,but its performance is better, its standard is higher. Compared with the common lining film woven bag,these bags can avoid the phenomenon that the inner lining film drop from the outer woven cloth by crash from putting goods into it.This bag can be produced continually,efficiently,quickly in the production line.It`s labor-saving and can be produced with large-scale. In contrast,inserting lining film to tubular woven cloth by handwork or turning outer layer to inner layer by handwork both are disconnected and inefficient.Bags produced by this machine is widely used for packaging of industries such as chemical materials,fertilizer,feed and food,etc.

Feature:

This horizontal type production line is equipped with retractable,advance & retreat type heating and laminating device.It is saving space,convenient to receive product,saving material,saving energy and working fast.

|

Specifications |

|

|

Type |

MX-650 |

|

Max. bonding width(mm) |

300~650 |

|

Max. bonding speed(mm) |

50 |

|

Max. rewinding diameter(mm) |

1200 |

|

Total power(kW) |

50 |

|

Dimension(L×W×H)(m) |

17×1.1×2.5 |